Transportatıon

DS-xR Solution for Smart Railway Transportation

Delphisonic DS-xR Real-Time Railway Condition Monitoring Solutions

Condition monitoring with modular service offerings

With Delphisonic DS-xR you will find the flexibility you need. Focused on you, our client, we adapt our service to your requirements.

- Delphisonic DS-xR Real-Time Railway Condition Monitoring Solutions

Together with our partners, we coordinate building, mounting and handing over of the systems as a fully operational solution. You will receive a DS-xR system that is absolutely ready to go. - Customer-specific solutions. With our DS-X Cloud-Based Software, your vibration specialists can use all monitoring and diagnostic functions without external support.

- Combination of both solutions. Would you like to manage the operation and maintenance of your monitoring system and database server yourself? And still have access to diagnostic experts to assess your maintenance needs? Simply select the relevant components from our modular range of services.

The DS-xR Condition Monitoring System is specifically designed for continuous permanent monitoring of railway vehicle generator machine trains. It is designed for monitoring applications that require extremely high reliability and availability. Applications that will be addressed by the DS-xR System include but are not limited to:

Bogie Main Bearing:

Outer race

Inner race

Inner race

Ball damage

Cocked bearing on the shaft

Cocked bearing in the housing

Cage damage

Creeping damage

Radial and axial clearance

Overload

Main Engine

Broken/cracked rotor bars

Loses rotor bar joints

Stator eccentricity

Eccentric rotor

Thermal rotor blow

The loose rotor on the shaft

Loose stator windings

Shorted laminations

Loose connector phasing

Leakage defects

Gear Boxes

Tooth skiving

Tooth wear

All Gear-meshes

Overload

Eccentricity

Misaligned

Backlash

Cracked and broken tooth

Hunting tooth frequency

Coupling

Coupling unbalance

In-parallel coupling faces

Coupling wear

Coupling misalignment

Locked coupling

Wedge damage

The wheel-rail mechanism

Wheel wear

Rail crack or breakage

Rail wear and slip

Rail joints

Generator Grounding

Special configuration or modifications to a standard monitor can be addressed through Delphi Sonic’s Custom Products Engineering. Contact your local Delphi Sonic sales professional for further information.

The Crucial Quality Advantages

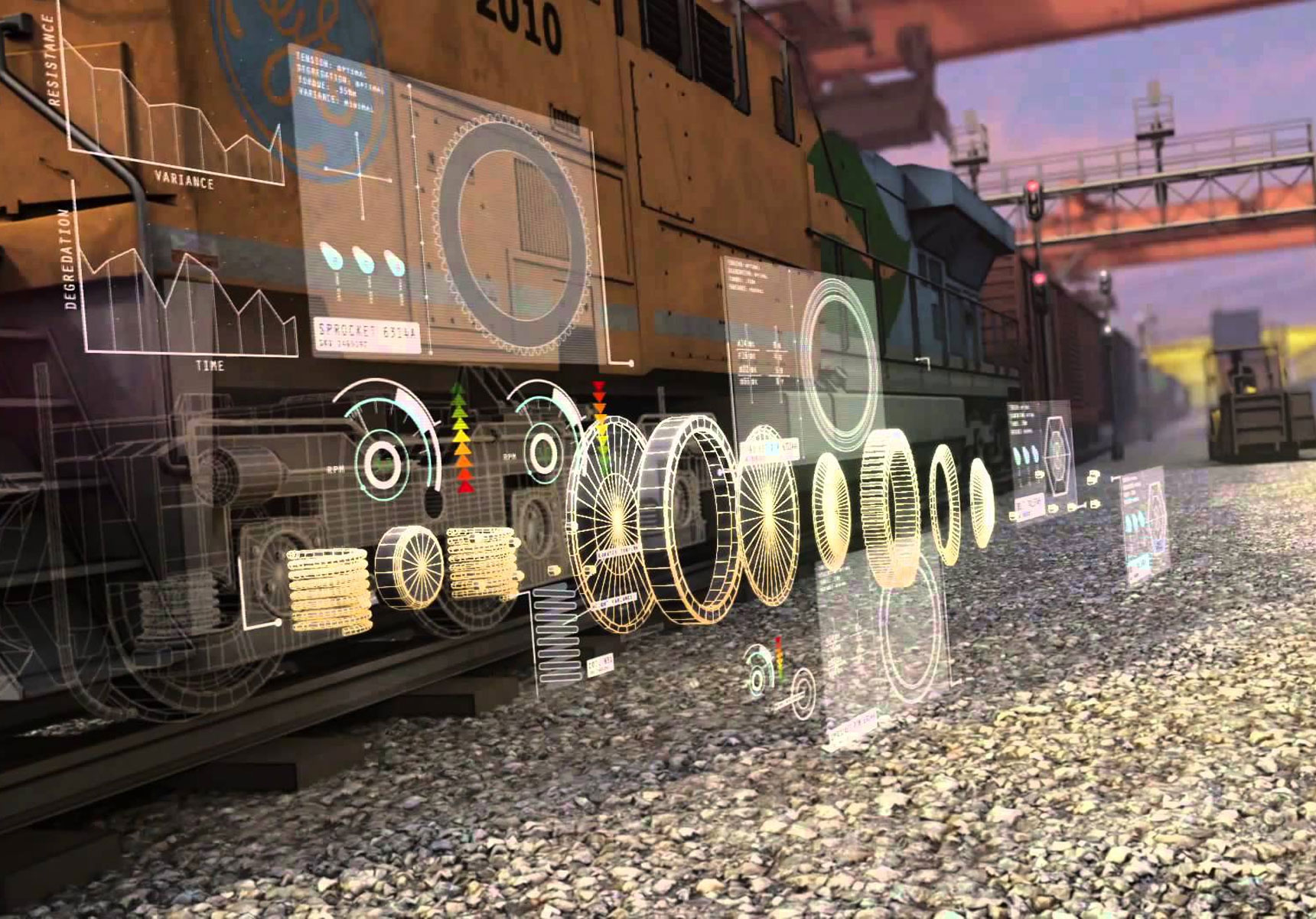

Railway equipment is large and complex. Anticipating repairs and addressing issues early can save time and money. DS-xR Railway Real-Time Condition Monitoring System helps engineers to understand the health of machinery and avoid downtime.

Readmore

Reaching the rail industry’s goals of increased maintenance intervals and maintenance-free targets of more than one and a half million kilometers requires transitioning from time-based maintenance schedules to condition-based maintenance. This ensures vehicles are only taken out of service for maintenance when it’s actually necessary.

Delphisonic DS-xR for Smart Railway Transportation Solutions use condition detection systems and sophisticated data processing algorithms to detect incipient damage. This allows sufficient time for repairs before significant mechanical failures can develop, helping to increase reliability and safety, while contributing to reduced maintenance time and costs, life cycle costs and total cost of ownership.

Fast and flexible

From components to full systems, Delphisonic is a proven technology supplier with full bogie monitoring solutions ready to go, as well as customized technology options.

Readmore

Benefits of DS real-time condition monitoring:

- Bogie maintenance cost reduction

- Extension of maintenance intervals

- Simplifying maintenance tasks

- Reduced spare parts stock

- Increase profitably by reducing unplanned downtime

- Eliminate false alarms of hotbox detectors

- Early identification of imminent failures

- Better component traceability

- Increased workshop effectiveness

- Reduce maintenance work time

- Eliminate field testing

- Check maintenance completion

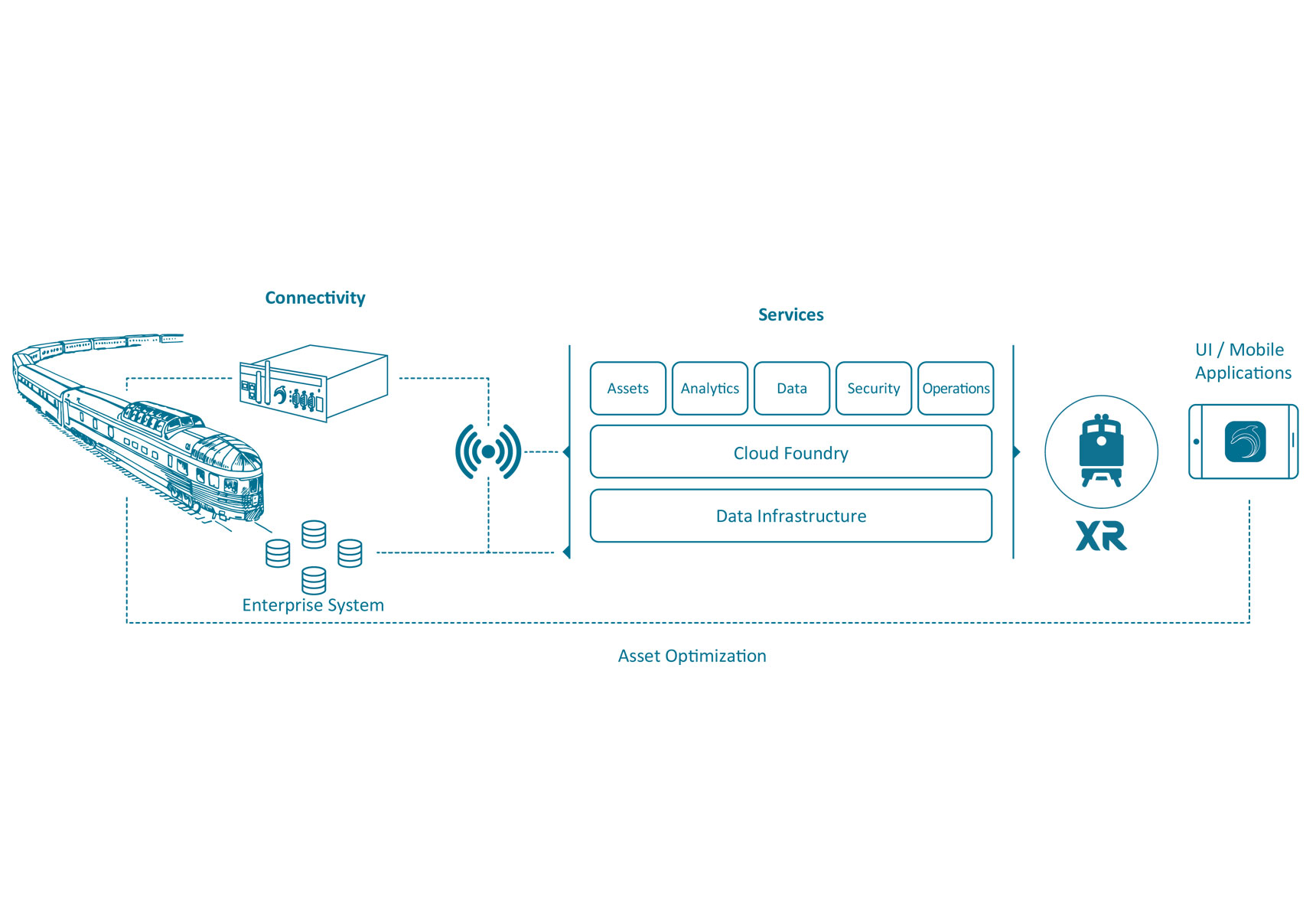

How it works;

- Our solution includes both Hardware (DS-xR) and Software (DS-X).

Developing a smart, problem-oriented analysis system that uses the Internet of Things (IoT) to remotely monitor the facility in real time, quickly convert large amounts of data to facility management, and immediately detect facility abnormities. The system must also improve overall facility efficiency, cost saving, reduce maintenance time-cost, and enhance travel safety.

Readmore

Our solution includes both Hardware and Software.

– Vibration sensors in addition to speed, pressure and temperature sensors that listen for problems in a train’s mechanical system and can predict when and where a failure or breakdown will happen. And with a software, engineers can monitor the HEALTH of their systems.