Problems

Railway

Maintenance Challenges

Rail systems operate under demanding and dynamic conditions, depending on high-speed mechanical components, heavy loads, and continuous motion across vast networks. Unplanned failures in these systems not only result in costly service disruptions and maintenance operations, but also pose serious risks to passenger safety, infrastructure integrity, and overall network performance.

The Most Common Railroad Malfunctions and Their Causes

These types of failures in railway systems reduce operating efficiency, increase

maintenance costs and pose a risk to passenger transportation.

Wheel-Rail Mechanism

Faults

Wheel wear

Rail cracks or breakage

Rail wear and slip detection

Rail joint issues

Generator & Electrical

Faults

Generator grounding

problems

Loose connector phasing

Shorted laminations

Loose stator windings

Main Engine & Rotor Issues

Broken or cracked rotor

bars

Loose rotor bar joints

Stator eccentricity

Eccentric rotor issues

Thermal rotor blow

Loose rotor on the shaft

Bogie & Bearing Issues

Outer race damage

Inner race damage

Ball damage

Cocked bearing on the shaft

Cocked bearing in the housing

Cage damage

Creeping damage

Radial and axial clearance issues

Overload failures

Gearbox Failures

Tooth skiving

Tooth wear

All gear-mesh anomalies

Overload conditions

Eccentricity issues

Misalignment

Excessive backlash

Cracked or broken teeth

Hunting tooth frequency detection

Coupling Issues

Coupling unbalance

In-parallel coupling faces misalignment

Coupling wear & tear

Locked coupling issues

Wedge damage

Solutions

DS-XR Revolutionizing Railway Maintenance with AI

Minimize Downtime, Reduce Costs, Maximize Safety!

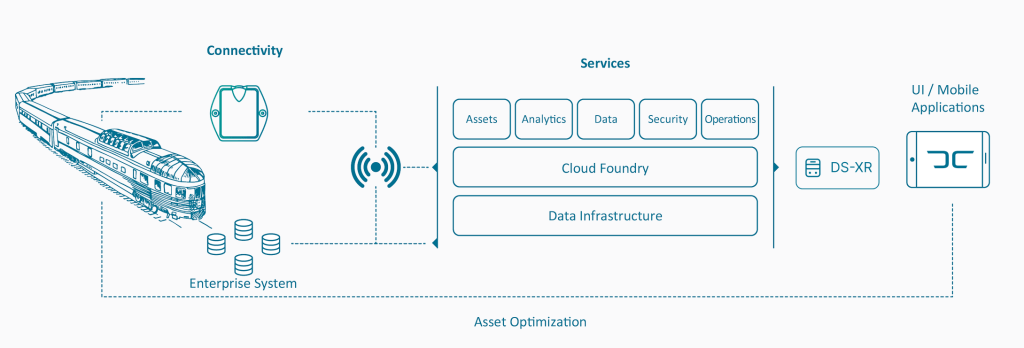

Traditional railway maintenance depends on periodic inspections and reactive fixes—often after faults have caused delays or damage.But in modern rail systems, AI-powered predictive maintenance is essential to maintain safety and efficiency. DS-XR integrates DS-Track sensors with the DS-Insight platform, enabling real-time monitoring of rolling stock and track conditions, and detecting faults before they lead to service disruptions.

How it Works

Delphisonic’s predictive maintenance system continuously monitors railway equipment with smart sensors and an AI-powered analytics platform. DS-Track collects real-time data from critical components on locomotives and infrastructure. This data is processed by DS-Insight to detect early signs of failure, optimize maintenance processes and prevent unplanned downtime. The result: safer, more efficient and uninterrupted railway operations.

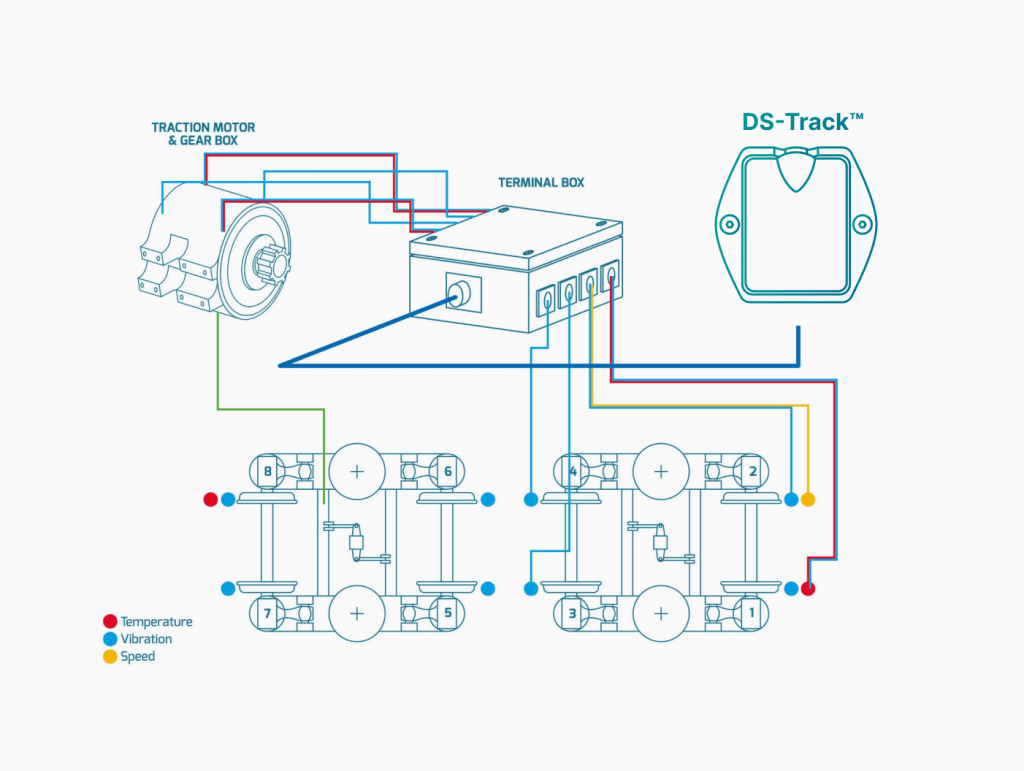

DS-Track

DS-Track is a smart sensor that can be easily installed on locomotives, railcars and infrastructure. The sensors continuously monitor vibration, temperature and other critical parameters and collect data in real time. The installation steps are as follows: First, the sensors are installed on the bogies, wheel sets, gearboxes and other critical components. Then, data is sent to the DS-Insight software via wireless or wired connections. Finally, real-time analysis detects potential faults and generates alerts.

DS-Insight

DS-Insight, AI destekli veri işleme ve analiz sağlayan bir yazılımdır. İşleyişi şu şekilde gerçekleşir: İlk olarak, DS-Track sensörlerinden anlık titreşim, sıcaklık ve dinamik yük verileri toplanır. Ardından, bu ham veriler DS-Insight’a iletilir ve AI destekli analiz motoru tarafından işlenir. Analiz sırasında algoritmalar, anormal titreşimleri, aşınma belirtilerini ve olası arızaları tespit eder. Sistem, kritik sorunlar için operatörleri uyararak bakım önerileri sunar. Son olarak, veriler kullanıcı dostu panelden görüntülenir ve bakım ekipleri hızlıca müdahale eder.

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Data is analyzed locally in real time for early anomaly detection.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Operators take targeted, fast action based on precise insights.

Continuous monitoring of vibration, temperature, and load data.

Data is sent to the central platform for deeper analysis and long-term tracking.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Entire flow is tailored through DS modules for each industry

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Continuous monitoring of vibration, temperature, and load data.

Data is analyzed locally in real time for early anomaly detection.

Data is sent to the central platform for deeper analysis and long-term tracking.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Operators take targeted, fast action based on precise insights.

Entire flow is tailored through DS modules for each industry

Key Benefits for

Railway Operations with Delphisonic

Up to 95% failure prevention through real-time condition monitoring and Edge AI-driven anomaly detection — minimizing unplanned maintenance and unexpected breakdowns.

<span data-metadata=""><span data-buffer="">Up to 30% reduction in maintenance costs by enabling data-driven scheduling and eliminating unnecessary part replacements.

<span data-metadata=""><span data-buffer="">Enhanced safety and reliability with early warnings for mechanical faults such as bearing wear, wheelset imbalance, and gearbox failures — reducing the risk of derailments or infrastructure damage.

<span data-metadata=""><span data-buffer="">Increased operational efficiency by ensuring system uptime, improving asset utilization, and reducing emergency interventions.

Discover Delphisonic’s solutions to optimize your maintenance

processes and reduce operational risks and costs.

A Greener Future on Steel

Low energy, low emissions: The power of sustainability on rails

Rail transport maximizes energy efficiency thanks to the low-friction movement of

steel wheels on steel rails. With the integration of electrification and renewable

energy sources, it becomes a truly eco-friendly transportation solution by

minimizing carbon emissions.

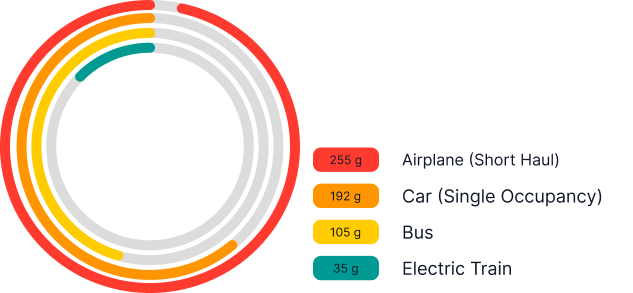

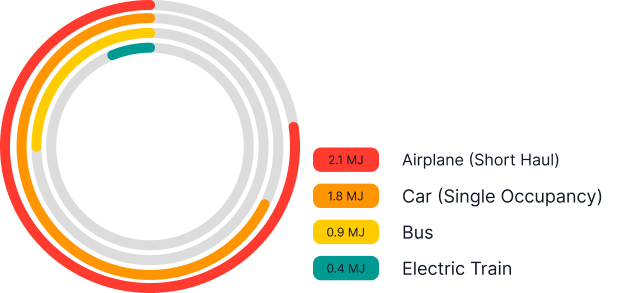

CO₂ Emissions by Transport Mode

Rail emits up to 7x less CO₂ than road, and up to 8x less than air travel.

Sources:

• Our World in Data – Travel Carbon Footprint

• IEA – The Future of Rail

CO₂ Emissions by Transport Mode

Rail emits up to 7x less CO₂ than road, and up to 8x less than air travel.

Sources:

• Our World in Data – Travel Carbon Footprint

• IEA – The Future of Rail

The Safest Track: Rail

An infrastructure built to move people — not risk

Rail transport has one of the lowest fatality rates among all motorized modes of

transportation. Dedicated infrastructure, automated signaling, and continuous

monitoring drastically reduce the risk of accidents.

Passenger Fatalities

Rail is around 70 times safer than road transport,and ranks among the safest motorized systems globally.

Sources:

• Eurostat – Railway Accident Statistics

• ETSC – Road Safety Progress

• Our World in Data – Transport Safety

Demand & Efficiency

The Backbone of Future Mobility:

Driven by urbanization, sustainability goals, and rising freight demands, rail is

becoming the most strategic transport infrastructure of the 21st century. By 2050,

global rail demand for both passengers and freight is expected to more than

double. With its capacity to carry thousands of passengers or tons of cargo in a

single trip, it offers a highly efficient and scalable solution.

Global Rail Demand Projections

According to the OECD and IEA, rail will become the backbone of global transport.Road and air infrastructure alone will not be able to meet future demand efficiently.

Sources:

• OECD ITF – Transport Outlook 2023

• IEA – The Future of Rail

Global Rail Demand Projections

According to the OECD and IEA, rail will become the backbone of global transport.Road and air infrastructure alone will not be able to meet future demand efficiently.

Sources:

• OECD ITF – Transport Outlook 2023

• IEA – The Future of Rail

AI-Driven Transformation

The Shift to Smart, Proactive Maintenance

Traditional railway maintenance relies on reactive or time-based interventions —

costly, risky, and inefficient. AI-powered predictive maintenance systems detect

early-stage faults before failures occur, enabling targeted, condition-based

interventions. This approach drastically reduces both downtime and maintenance

spend, while increasing system reliability.

Benefits of Predictive Maintenance

With platforms like DS-Insight, real-time sensor data is analyzed using machine learning to detect faults before they escalate.

Sources:

• McKinsey – Future of Rail Maintenance

• US DOE – Predictive Maintenance Guide

• [Delphisonic Field Data, 2024]

Why Delphisonic?

Delphisonic’s Railway Expertise

At Delphisonic, we have been delivering predictive maintenance and industrial monitoring solutions since 2012 — with a strong focus on the railway industry.

We combine AI-powered analytics with edge-based smart sensors to detect failures early, lower maintenance costs, and ensure uninterrupted operations.

We don’t just monitor rail systems — we engineer them from within, with deep technical know-how and industry-specific insight.

Let’s solve your railway challenges together.

Guide the future

Request a Demo

Solutions

Trust Center

Solutions

Trust Center

Solutions

Trust Center

© Copyright 2025, All Rights Reserved by Delphisonic