AI-Powered

Predictive Maintenance

Smarter maintenance decisions backed by edge-processed data, real-time analytics, and industry-specific insight.

Trusted by Clients, Partners & Global Alliances

Built on Collaboration,

Powered by Intelligence

A Complete Predictive Maintenance Ecosystem

From data capture to decision-making, Delphisonic delivers a complete predictive maintenance cycle.Our AI-powered platform combines sensor hardware, real-time analytics, alert management, and intuitive dashboards to turn raw asset data into actionable insights. This integrated approach enables early fault detection, optimized maintenance strategies, and increased operational efficiency—across rail, marine, energy, and industrial sectors.

DS-Track ™

Real-Time Data Collection at Its Best

DS-Track is a compact smart sensor that monitors vibration, temperature, and structural anomalies in real time—processing data directly on-device with embedded Edge AI. Designed for harsh industrial environments, it delivers instant alerts, seamless integration, and fault detection up to 10x faster than cloud-based systems—minimizing downtime and maintenance costs.

DS-Insight

Transforming Data into Smart Decisions

DS-Insight is a modular analytics platform that turns real-time data into predictive insights with AI-powered analysis, intelligent alerts, and interactive dashboards. Designed for rail, energy, marine, and aviation, it adapts to any asset type—minimizing downtime, improving reliability, and scaling across industries.

21+

Counteries Served

1000+

Sensors Deployed

7+

Industries Served

2012

In Business Since 2012

Industry-Spesific

Predictive Maintenance

Solutions

Predictive Maintenance

Predictive

Maintenance

Optimize Rail Operations & Reduce Downtime

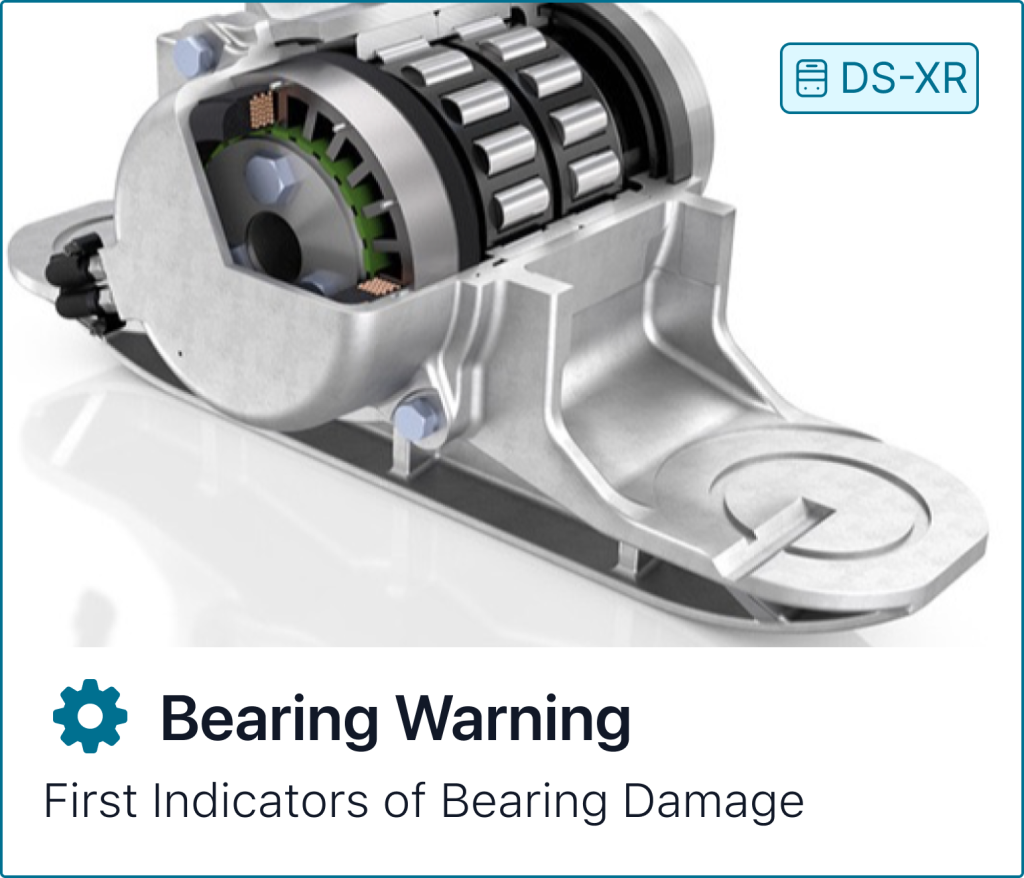

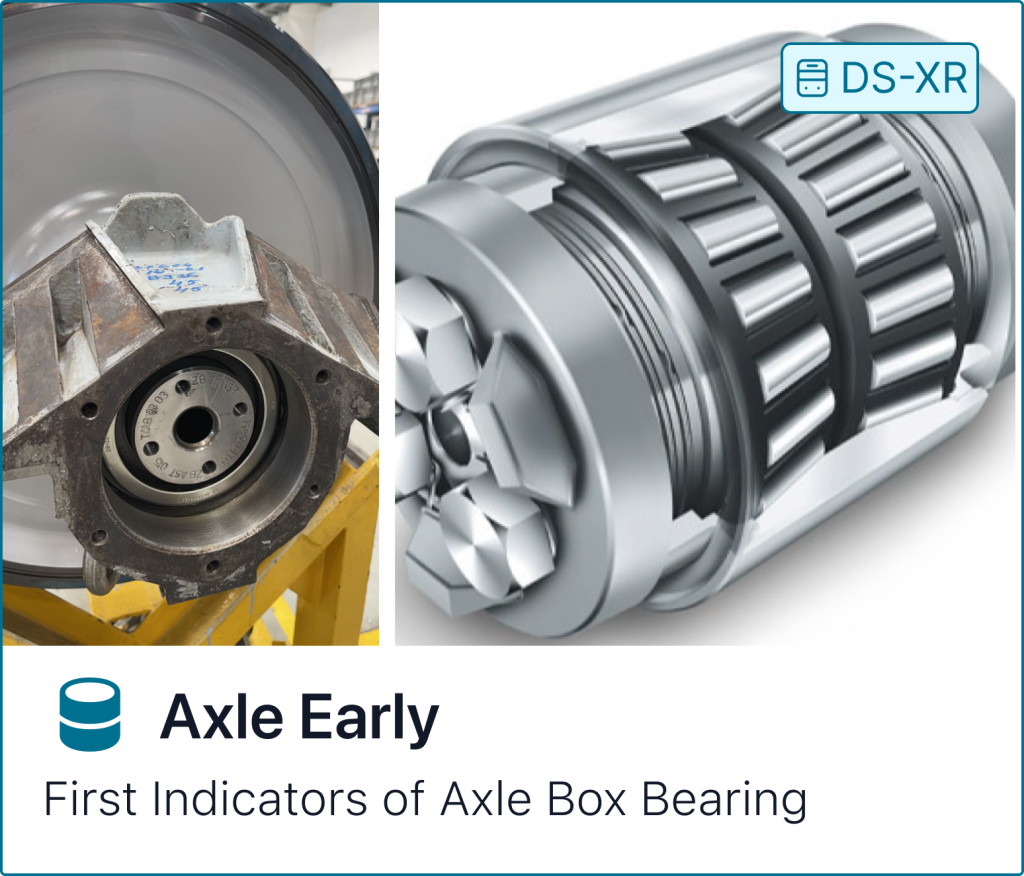

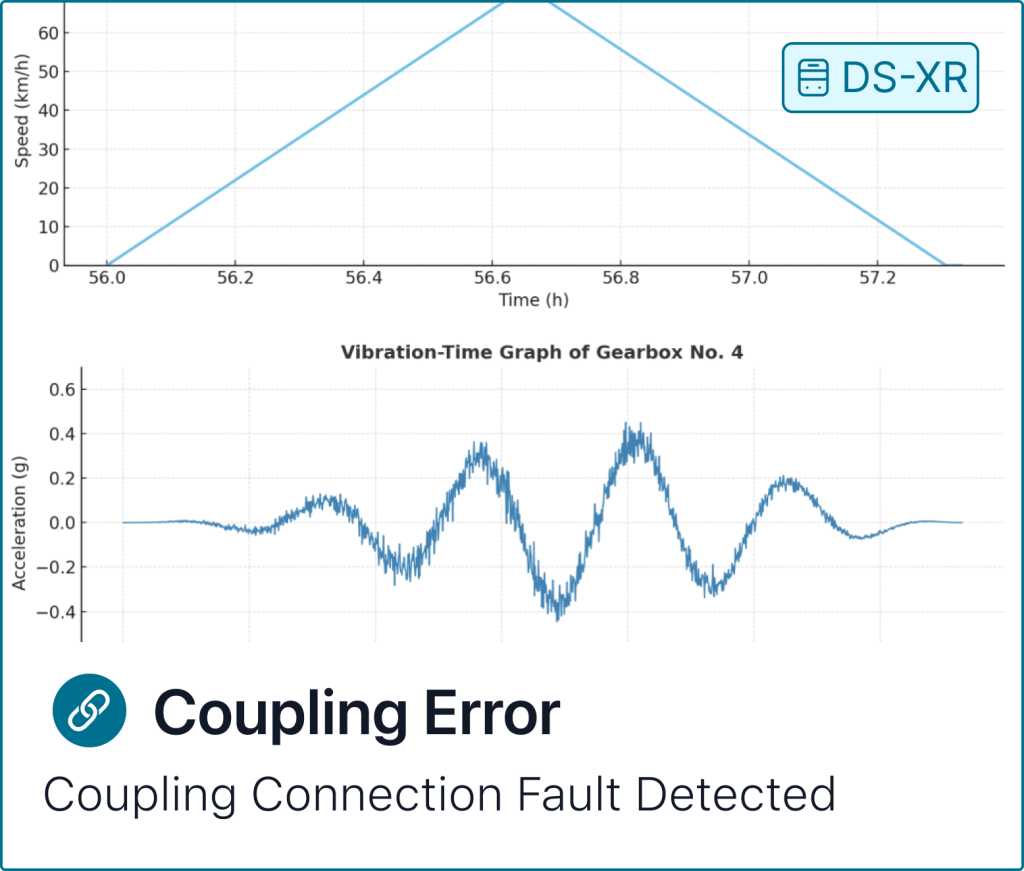

Railway systems face constant wear and tear, leading to unexpected failures, costly repairs, and operational disruptions. DS-XR provides real-time condition monitoring for trains and tracks, detecting axle overheating, brake failures, misalignments, and component wear before they escalate. By leveraging AI-driven predictive analytics, DS-XR reduces unplanned downtime, enhances safety, and extends asset lifespan—keeping railway operations running smoothly and efficiently.

Wind Turbine &

Renewable Energy

Optimization

Wind Turbine &

Renewable

Energy Optimization

Keep Your Wind Turbines Running at Peak Efficiency

Wind turbines and renewable energy assets require continuous monitoring to prevent performance losses and mechanical failures. DS-WG analyzes blade stress, gearbox performance, generator health, and environmental conditions to predict early-stage failures and optimize maintenance schedules. By providing AI-based insights and real-time alerts, DS-WG maximizes energy output, reduces maintenance costs, and extends the lifespan of renewable energy assets.

Smart Monitoring

for Oil & Gas

Infrastructure

Smart Monitoring

for Oil &

Gas Infrastructure

Enhance Safety & Reliability in Critical Operations

The oil & gas sector demands high reliability and proactive risk management due to harsh operating environments and high-pressure systems. DS-GO provides real-time pipeline integrity monitoring, leak detection, pressure anomaly identification, and pump health analysis to prevent catastrophic failures and costly downtimes. By utilizing AI-powered predictive analytics, DS-GO optimizes maintenance, ensures compliance, and enhances safety in oil & gas operations.

Intelligent Monitoring

for Marine & Shipping

Intelligent Monitoring for

Marine & Shipping

Ensure Smooth Sailing with AI-Powered Insights

Maritime operations are exposed to harsh environments, mechanical fatigue, and unpredictable failures. DS-SP continuously tracks engine health, hull integrity, vibration patterns, and fuel efficiency, helping ship operators prevent unexpected breakdowns and optimize maintenance schedules. With early fault detection and real-time alerts, DS-SP improves fleet reliability, lowers maintenance costs, and enhances operational efficiency across marine and shipping industries.

Engine & Turbine

HealthMonitoring

Engine & Turbine Health

Monitoring

Maximize Performance, Minimize Risk

Aircraft engines and industrial turbines operate under high stress and extreme conditions, making early fault detection crucial. DS-AP offers real-time anomaly detection, vibration analysis, and thermal monitoring, helping maintenance teams predict bearing failures, rotor imbalances, and overheating risks before they cause system failures. With AI-powered diagnostics, DS-AP enhances safety, improves efficiency, and extends the operational life of critical assets.

Industrial Manufacturing

Optimization

Minimize Downtime, Maximize Productivity

Manufacturing plants rely on continuous production flow, but unexpected machinery failures can lead to costly delays. DS-IN integrates sensor-driven monitoring, AI-driven analytics, and automated alerts to identify motor failures, misalignments, excessive vibrations, and lubrication issues before they impact production. By enabling predictive maintenance strategies, DS-IN reduces downtime, enhances equipment longevity, and boosts overall efficiency.

Why Delphisonic?

Reduce downtime, cut maintenance costs, and enhance efficiency

with AI-powered predictive maintenance solutions.

95% Failure Prevention

Predict Issues Before They Happen AI-powered sensors detect early signs of failure, minimizing unplanned downtime and costly breakdowns.

30% Cost Reduction

Optimize Maintenance Costs Preventive insights help reduce unnecessary repairs, extending equipment lifespan and lowering expenses.

Plug & Play

Instant Monitoring, Zero Hassle Simply install the DS device and start tracking critical data in real time—no complex setup required.

Real-Time AI Insights

Make Data-Driven Decisions Live monitoring and smart alerts provide instant visibility into asset health, ensuring efficient operations.

DS-Blog

In this section you find our latest company news and various resources around topics that matter to us:

Industry 4.0, Industrial IoT, Artificial Intelligence and start-up working culture.

Delphisonic to Exhibit at Middle East Rail 2025 – Visit Us in Dubai!

Inside Delphisonic’s Smart Sensor Architecture: Hardware, Algorithms, and Intelligence

Guide the future

Request a Demo

Solutions

Trust Center

Solutions

Trust Center

Solutions

Trust Center

© Copyright 2025, All Rights Reserved by Delphisonic