Problems

Marine

Maintenance Challenges

Marine vessels operate in harsh and unpredictable environments, relying on complex mechanical systems that run continuously over long distances. Unplanned failures in these systems not only lead to costly delays and maintenance expenses, but also pose serious risks to crew safety, cargo integrity, and vessel performance.

Problems

Marine Maintenance Challenges

Marine vessels operate in harsh and unpredictable environments, relying on complex mechanical systems that run continuously over long distances. Unplanned failures in these systems not only lead to costly delays and maintenance expenses, but also pose serious risks to crew safety, cargo integrity, and vessel performance.

Common Marine System

Failures and Root Causes

Such failures in marine systems reduce operational efficiency, increase

maintenance costs, and pose significant risks to crew safety and cargo integrity.

Propulsion System Issues

• Propeller shaft misalignment

• Cavitation damage

• Shaft vibration

• Bearing overheating

• Seal leakage

• Structural fatigue at stern tube

Engine & Generator Failures

• Cylinder misfiring

• Cracked or warped cylinder heads

• Rotor imbalance

• Loose stator windings

• Insulation degradation

• Generator grounding faults

• Voltage and frequency instability

Gearbox & Transmission Problems

• Gear tooth wear

• Lubrication failure

• Cracked or broken gears

• Misalignment and backlash

• Overload under torque spikes

• Bearing pitting and spalling

Common Marine System

Failures and Root Causes

Such failures in marine systems reduce operational efficiency, increase

maintenance costs, and pose significant risks to crew safety and cargo integrity.

Propulsion System Issues

• Propeller shaft misalignment

• Cavitation damage

• Shaft vibration

• Bearing overheating

• Seal leakage

• Structural fatigue at stern tube

Engine & Generator Failures

• Cylinder misfiring

• Cracked or warped cylinder heads

• Rotor imbalance

• Loose stator windings

• Insulation degradation

• Generator grounding faults

• Voltage and frequency instability

Gearbox & Transmission Problems

• Gear tooth wear

• Lubrication failure

• Cracked or broken gears

• Misalignment and backlash

• Overload under torque spikes

• Bearing pitting and spalling

Pumps & Hydraulic System

Malfunctions

• Pressure loss

• Internal leakage

• Cavitation in impellers

• Motor overheating

• Valve and actuator failures

Coupling & Alignment Issues

• Coupling misalignment

• Excessive vibration at junctions

• Wear and tear under load

• Locked couplings

• Torsional stress failure

Pumps & Hydraulic System

Malfunctions

• Pressure loss

• Internal leakage

• Cavitation in impellers

• Motor overheating

• Valve and actuator failures

Coupling & Alignment Issues

• Coupling misalignment

• Excessive vibration at junctions

• Wear and tear under load

• Locked couplings

• Torsional stress failure

Solutions

DS-SP: Transforming Maritime Maintenance with AI

Minimize Downtime. Reduce Costs. Maximize Safety.

Traditional maritime maintenance often relies on scheduled checks or reactive repairs—leaving fleets vulnerable to costly failures. In today’s demanding operations, AI-powered predictive maintenance is essential. DS-SP combines DS-Track, an Edge AI smart sensor, with the DS-Insight platform to monitor engines, shafts, and auxiliary systems in real time. By processing data at the edge, it detects anomalies like cavitation, bearing wear, or misalignment before critical damage occurs—enabling proactive, data-driven maintenance at sea.

Solutions

DS-SP: Transforming Maritime Maintenance with AI

Minimize Downtime. Reduce Costs. Maximize Safety.

Traditional maritime maintenance often relies on scheduled checks or reactive repairs—leaving fleets vulnerable to costly failures. In today’s demanding operations, AI-powered predictive maintenance is essential. DS-SP combines DS-Track, an Edge AI smart sensor, with the DS-Insight platform to monitor engines, shafts, and auxiliary systems in real time. By processing data at the edge, it detects anomalies like cavitation, bearing wear, or misalignment before critical damage occurs—enabling proactive, data-driven maintenance at sea.

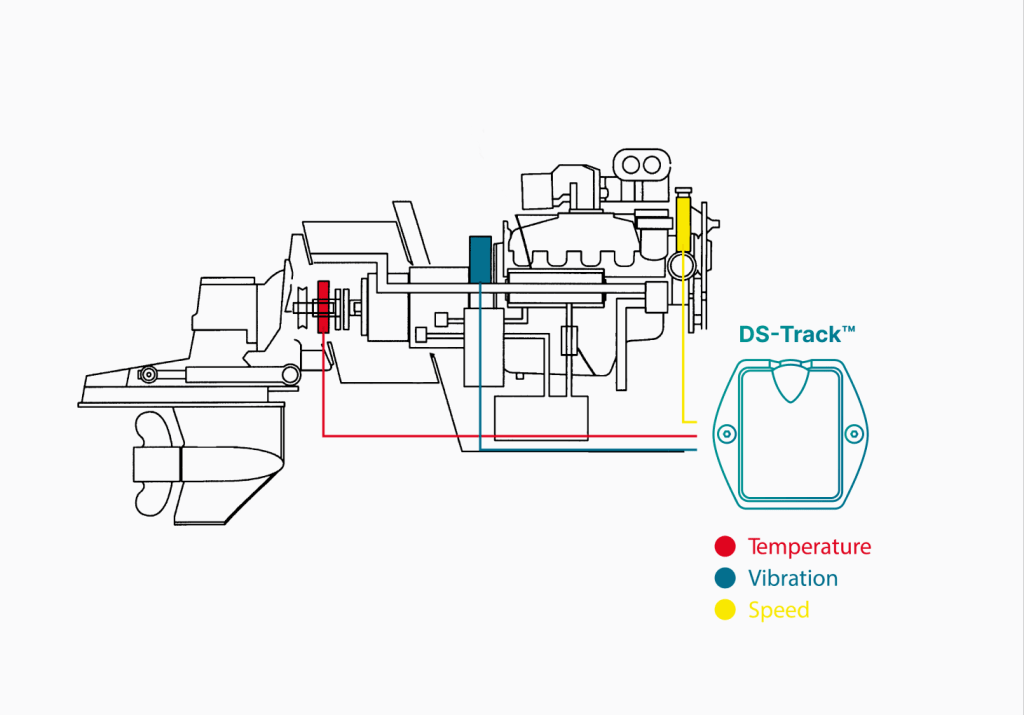

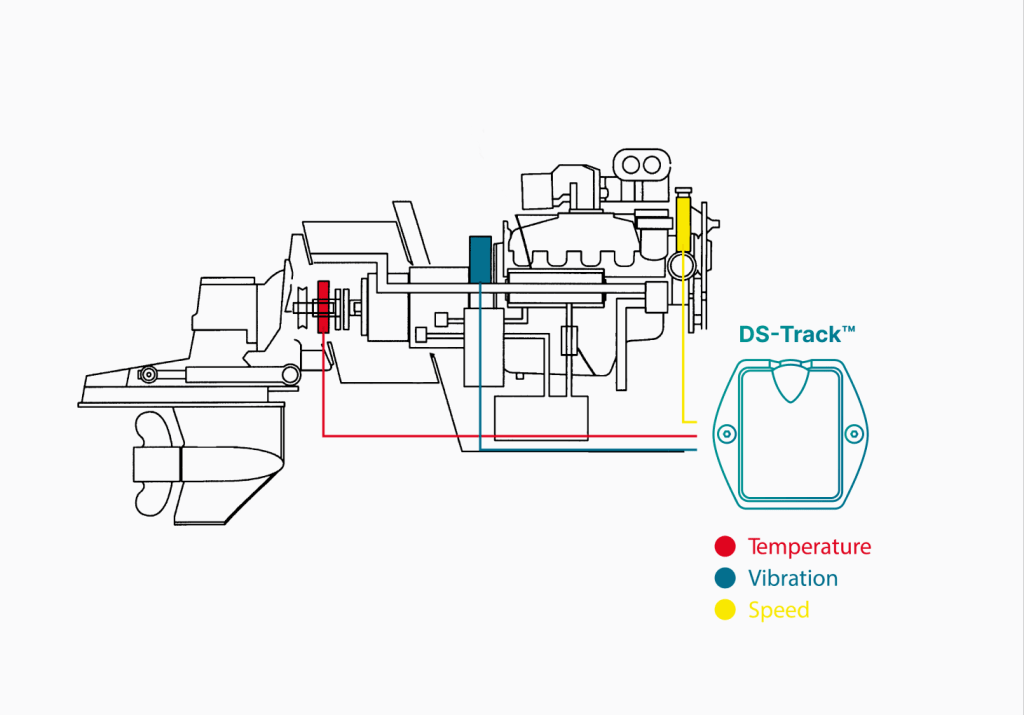

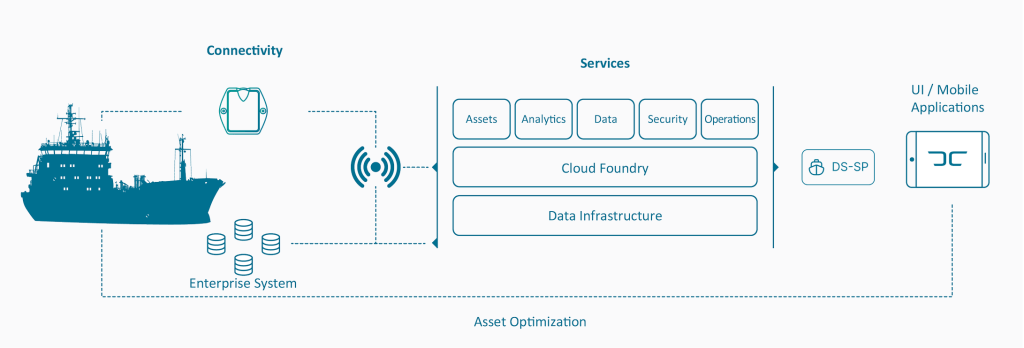

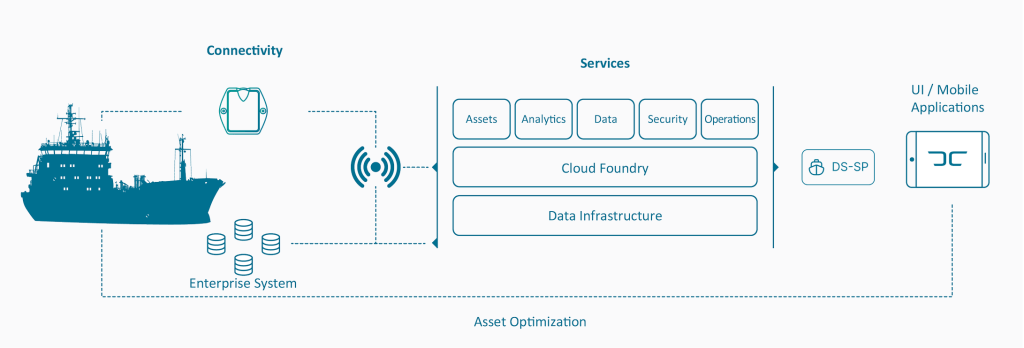

How it Works

Delphisonic’s predictive maintenance system combines Edge AI-powered DS-Track sensors with the DS-Insight analytics platform to continuously monitor marine systems in real time. Data is processed directly on the sensor, enabling early fault detection before failures occur. This helps optimize maintenance, reduce unplanned downtime, and increase vessel safety and operational efficiency.

How it works

Delphisonic’s predictive maintenance system combines Edge AI-powered DS-Track sensors with the DS-Insight analytics platform to continuously monitor marine systems in real time. Data is processed directly on the sensor, enabling early fault detection before failures occur. This helps optimize maintenance, reduce unplanned downtime, and increase vessel safety and operational efficiency.

DS-Track</span

DS-Track is an Edge AI-powered smart sensor that can be easily installed on marine equipment such as engines, propulsion shafts, gearboxes, and pumps. It continuously monitors critical parameters like vibration, temperature, and mechanical stress, processing the data locally in real time. The data is transmitted—via wired or wireless connections—to the DS-Insight platform, but most anomalies are detected directly on the sensor itself, allowing for early warnings and precise alerts before faults escalate into costly failures.

DS Track

DS-Track is an Edge AI-powered smart sensor that can be easily installed on marine equipment such as engines, propulsion shafts, gearboxes, and pumps. It continuously monitors critical parameters like vibration, temperature, and mechanical stress, processing the data locally in real time. The data is transmitted—via wired or wireless connections—to the DS-Insight platform, but most anomalies are detected directly on the sensor itself, allowing for early warnings and precise alerts before faults escalate into costly failures.

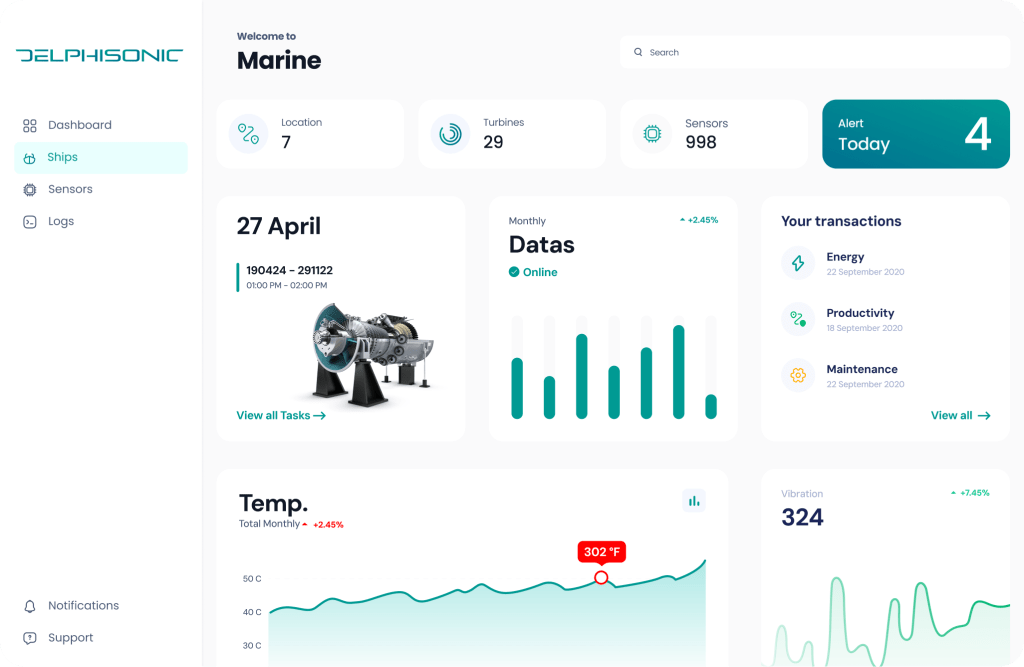

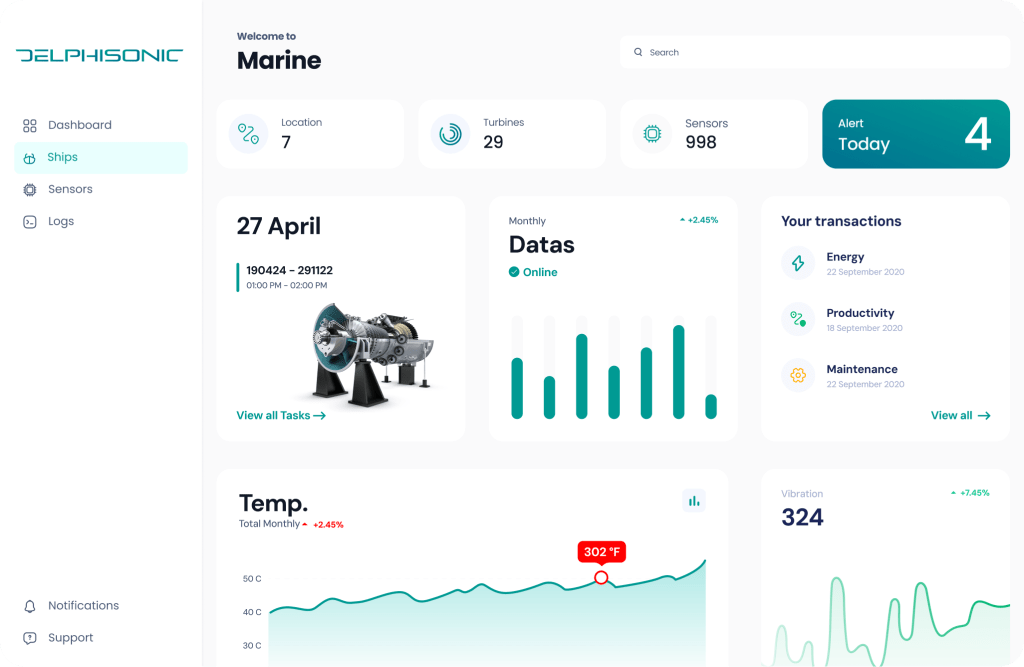

DS-Insight

DS-Insight is Delphisonic’s AI-powered platform for predictive maintenance, and the DS-SP module is specially designed for the marine and shipping industry. It analyzes real-time vibration, temperature, and load data from critical systems like engines, shafts, and gearboxes—detecting early-stage faults before they cause serious failures. Smart alarm filtering ensures that only actionable alerts are delivered, reducing noise and improving decision-making. With its intuitive interface and cloud access, DS-Insight with DS-SP helps marine operators optimize maintenance, increase safety, and reduce downtime across the fleet.

DS-Insight

DS-Insight is Delphisonic’s AI-powered platform for predictive maintenance, and the DS-SP module is specially designed for the marine and shipping industry. It analyzes real-time vibration, temperature, and load data from critical systems like engines, shafts, and gearboxes—detecting early-stage faults before they cause serious failures. Smart alarm filtering ensures that only actionable alerts are delivered, reducing noise and improving decision-making. With its intuitive interface and cloud access, DS-Insight with DS-SP helps marine operators optimize maintenance, increase safety, and reduce downtime across the fleet.

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Continuous monitoring of vibration, temperature, and load data.

Data is analyzed locally in real time for early anomaly detection.

Data is sent to the central platform for deeper analysis and long-term tracking.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Operators take targeted, fast action based on precise insights.

Entire flow is tailored through DS modules for each industry

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Data is analyzed locally in real time for early anomaly detection.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Operators take targeted, fast action based on precise insights.

Continuous monitoring of vibration, temperature, and load data.

Data is sent to the central platform for deeper analysis and long-term tracking.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Entire flow is tailored through DS modules for each industry

Key Benefits for

Maritime Operations with Delphisonic

Key Benefits for

Maritime Operations with Delphisonic

Up to 95% failure prevention through real-time monitoring of engines, propulsion shafts, gearboxes, and auxiliary systems — enabled by Edge AI anomaly detection to reduce costly downtime and emergency repairs.

Improved safety and operational reliability with early alerts on critical faults such as cavitation, bearing overheating, and shaft misalignment — minimizing the risk of onboard malfunctions and voyage disruptions.

Enhanced safety and reliability with early warnings for mechanical faults such as bearing wear, wheelset imbalance, and gearbox failures — reducing the risk of derailments or infrastructure damage.

Fleet-wide efficiency gains through enhanced equipment availability, reduced manual inspections, and smarter intervention timing — ensuring smoother operations for both cargo and passenger vessels.

Discover Delphisonic’s solutions to optimize your maintenance

processes and reduce operational risks and costs.

Discover Delphisonic’s solutions to optimize your maintenance

processes and reduce operational risks and costs.

Why Delphisonic?

Why Delphisonic?

Delphisonic’s Oil & Gas Expertise

At Delphisonic, we have been delivering predictive maintenance and industrial monitoring solutions since 2012 — with a strong focus on marine propulsion and shipboard systems.

We combine AI-powered analytics with edge-based smart sensors to detect failures early, reduce maintenance costs, and keep fleets operating safely and efficiently.

We don’t just monitor vessels — we engineer them from within, with deep technical know-how and maritime-specific insight.

Let’s solve your infrastructure challenges together.

Guide the future

Request a Demo

Guide the future

Request a Demo

Solutions

Trust Center

Solutions

Trust Center

Solutions

Trust Center

© Copyright 2025, All Rights Reserved by Delphisonic