Problems

Industrial Operations

Maintenance Challenges

Industrial production systems operate at high speeds with repetitive, tightly integrated mechanical components. Unplanned failures in these environments not only lead to costly downtime and repairs, but also shorten equipment lifespan and significantly compromise process reliability.

Problems

Industrial Operations Maintenance Challenges

Industrial production systems operate at high speeds with repetitive, tightly integrated mechanical components. Unplanned failures in these environments not only lead to costly downtime and repairs, but also shorten equipment lifespan and significantly compromise process reliability.

Common Industrial System

Failures and Root Causes

Such failures in industrial systems reduce operational reliability, increase

maintenance costs, and pose critical risks to equipment integrity and production

safety.

Bearing Systems

• Inner/outer race wear

• Ball or roller damage

• Cocked bearings

• Loss of axial/radial clearance

• Lubrication degradation or absence

Gearbox & Transmission

• Tooth wear or breakage

• Surface pitting and spalling

• Excessive backlash

• Gear misalignment

• Overload due to torque fluctuation

Rotor & Shaft Components

• Rotor imbalance

• Torsional vibration

• Shaft bending or cracks

• Loose rotor mounting

• Eccentric rotation under load

Common Industrial System

Failures and Root Causes

Such failures in industrial systems reduce operational reliability, increase

maintenance costs, and pose critical risks to equipment integrity and production

safety.

Bearing Systems

• Inner/outer race wear

• Ball or roller damage

• Cocked bearings

• Loss of axial/radial clearance

• Lubrication degradation or absence

Gearbox & Transmission

• Tooth wear or breakage

• Surface pitting and spalling

• Excessive backlash

• Gear misalignment

• Overload due to torque fluctuation

Rotor & Shaft Components

• Rotor imbalance

• Torsional vibration

• Shaft bending or cracks

• Loose rotor mounting

• Eccentric rotation under load

Sensor & Signal Anomalies

• Tachometer signal dropout

• Sensor drift or malfunction

• Electrical noise interference

• Loose wiring or incorrect phasing

Thermal & Structural Failures

• Thermal rotor distortion

• Loose stator windings

• Cracks from thermal cycling

• Heat-induced misalignment

Solutions

DS-IN: Enhancing Industrial Reliability with AI

Minimize Failures. Extend Lifespan. Ensure Safety.

Traditional industrial maintenance relies on fixed schedules and reactive repairs — often overlooking early-stage issues. In environments where reliability is essential, AI-powered predictive maintenance has become indispensable. DS-IN integrates DS-Track, an Edge AI-enabled smart sensor, with the DS-Insight platform to monitor motors, gearboxes, and rotating machinery in real time. By analyzing vibration and load data directly at the edge, it detects early indicators of faults such as bearing wear or rotor imbalance — before they escalate into costly downtime or production failures. imbalance—before they affect flight safety.

Solutions

DS-IN: Enhancing Industrial Reliability with AI

Minimize Failures. Extend Lifespan. Ensure Safety.

Traditional industrial maintenance relies on fixed schedules and reactive repairs — often overlooking early-stage issues. In environments where reliability is essential, AI-powered predictive maintenance has become indispensable. DS-IN integrates DS-Track, an Edge AI-enabled smart sensor, with the DS-Insight platform to monitor motors, gearboxes, and rotating machinery in real time. By analyzing vibration and load data directly at the edge, it detects early indicators of faults such as bearing wear or rotor imbalance — before they escalate into costly downtime or production failures. imbalance—before they affect flight safety.

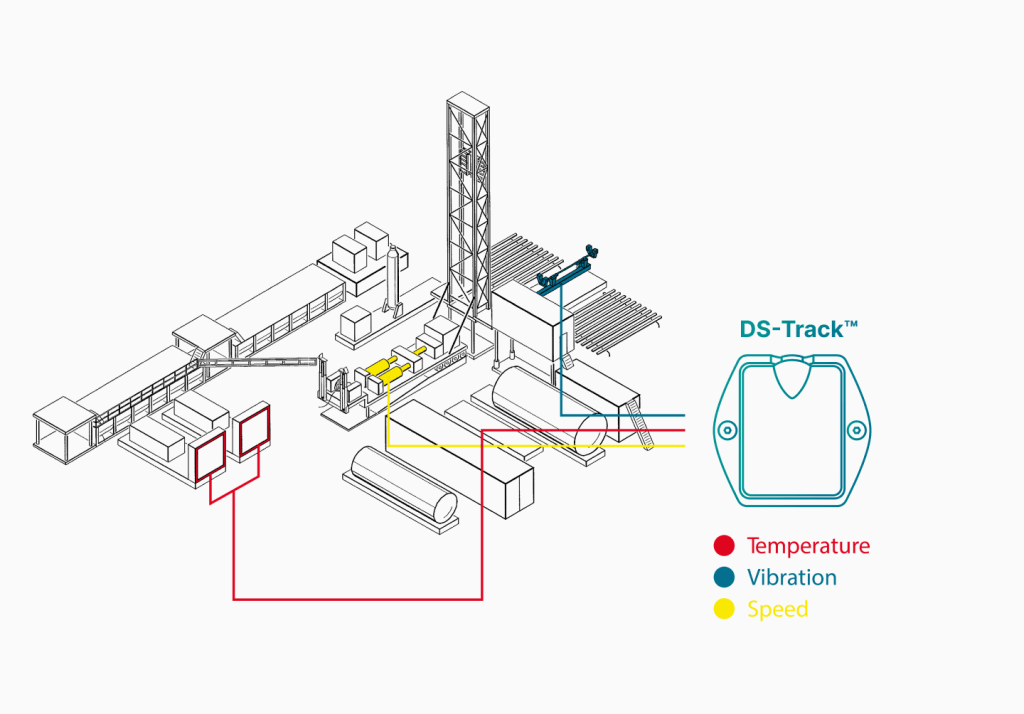

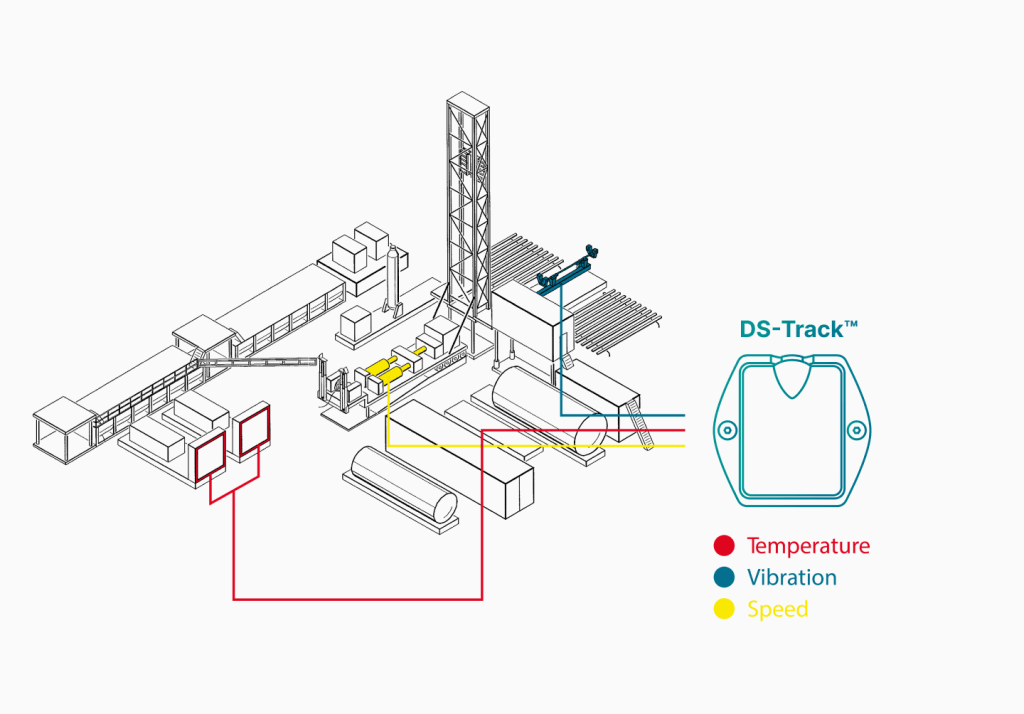

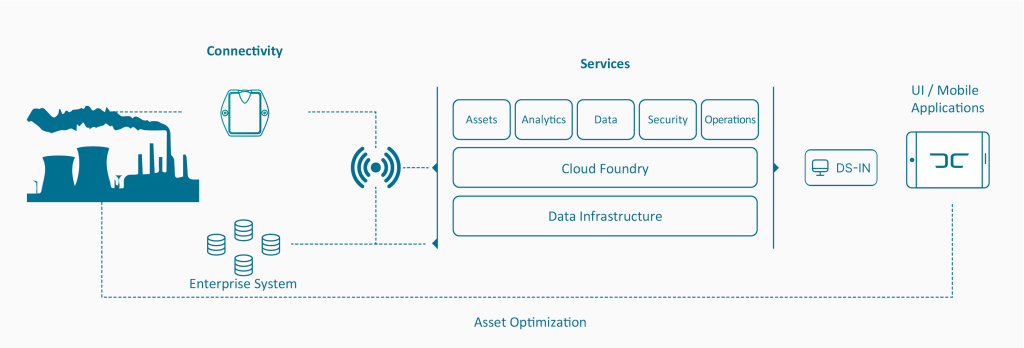

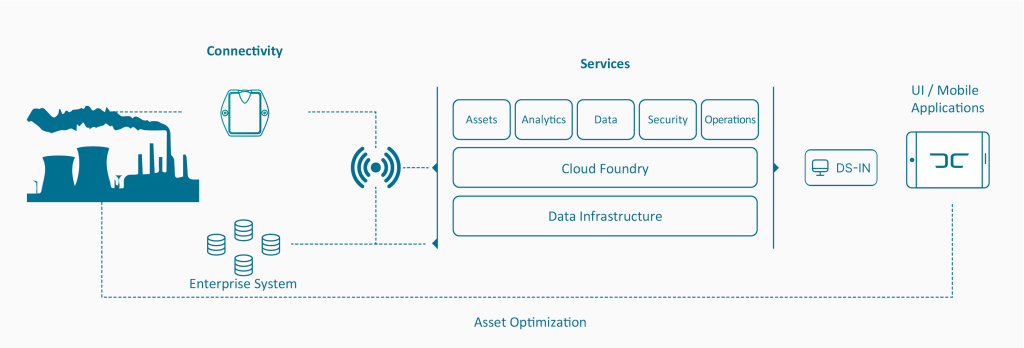

How it Works

Delphisonic’s predictive maintenance system combines Edge AI-powered DS-Track sensors with the DS-Insight analytics platform to continuously monitor industrial systems in real time. Data is processed directly on the sensor, enabling early fault detection before critical failures occur. This helps optimize maintenance planning, reduce unplanned downtime, and improve production reliability.

How it Works

Delphisonic’s predictive maintenance system combines Edge AI-powered DS-Track sensors with the DS-Insight analytics platform to continuously monitor industrial systems in real time. Data is processed directly on the sensor, enabling early fault detection before critical failures occur. This helps optimize maintenance planning, reduce unplanned downtime, and improve production reliability.Data is processed directly on the sensor, enabling early fault detection before critical failures occur. This helps optimize maintenance planning, reduce unplanned interventions, and enhance operational safety and system reliability.

DS-Track

DS-Track is an Edge AI-powered smart sensor that can be seamlessly integrated into industrial systems such as motors, gearboxes, pumps, and rotating equipment. It continuously monitors key parameters like vibration, temperature, and dynamic load, processing the data locally in real time. The data is transmitted—via wired or wireless connections—to the DS-Insight platform, but most anomalies are detected directly on the sensor itself. This enables early warnings and accurate alerts before failures occur, allowing maintenance teams to act proactively and prevent unplanned downtime.

DS-Track

DS-Track is an Edge AI-powered smart sensor that can be seamlessly integrated into industrial systems such as motors, gearboxes, pumps, and rotating equipment. It continuously monitors key parameters like vibration, temperature, and dynamic load, processing the data locally in real time. The data is transmitted—via wired or wireless connections—to the DS-Insight platform, but most anomalies are detected directly on the sensor itself. This enables early warnings and accurate alerts before failures occur, allowing maintenance teams to act proactively and prevent unplanned downtime.

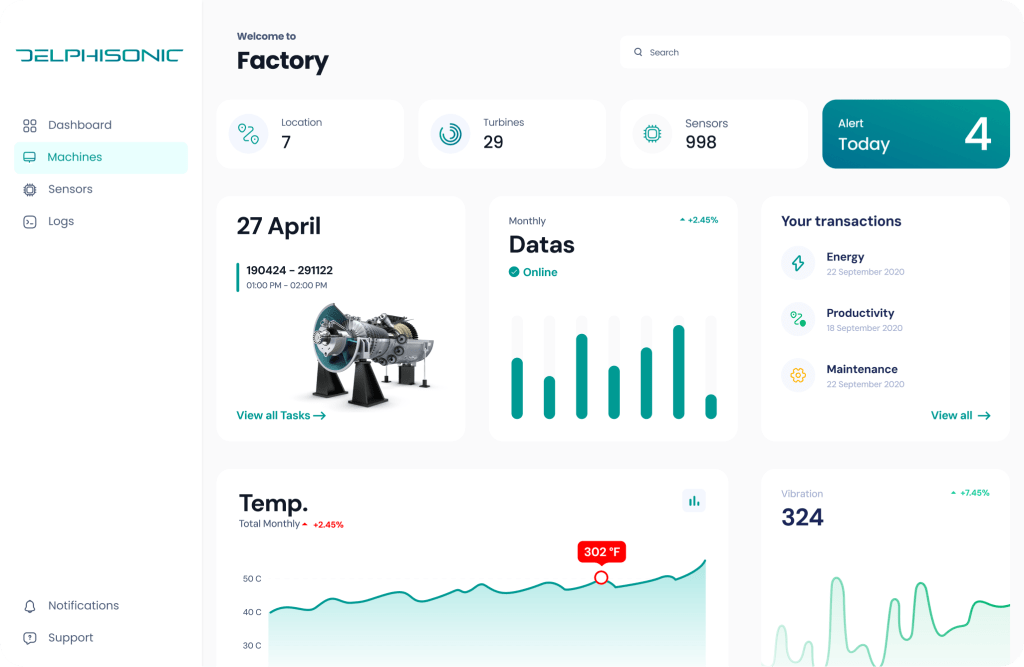

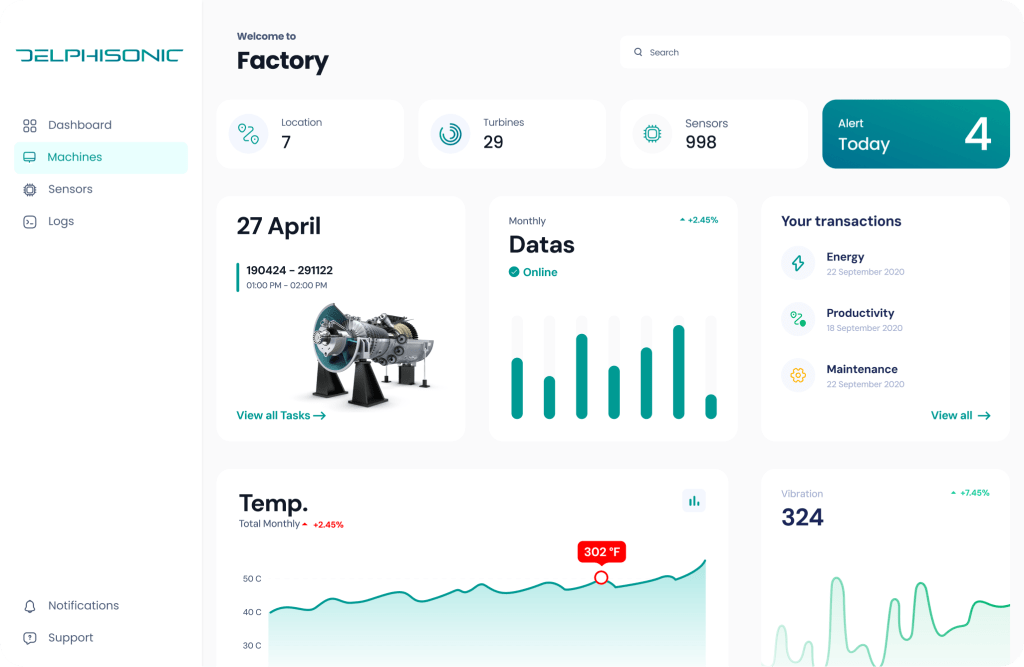

DS-Insight

DS-Insight is Delphisonic’s AI-powered predictive maintenance platform, and the DS-IN module is specifically developed for industrial assets such as motors, gearboxes, bearings, and pumps. It analyzes real-time data on vibration, temperature, and load—detecting early signs of failure before they disrupt operations. Its smart alarm filtering minimizes false positives and delivers only timely, actionable alerts. With an intuitive interface and cloud connectivity, DS-Insight with DS-IN helps industrial teams optimize maintenance schedules, improve system reliability, and minimize unplanned downtime.

DS-Insight

<span data-metadata=""><span data-metadata=""><span data-buffer="">DS-Insight is Delphisonic’s AI-powered predictive maintenance platform, and the DS-IN module is specifically developed for industrial assets such as motors, gearboxes, bearings, and pumps. It analyzes real-time data on vibration, temperature, and load—detecting early signs of failure before they disrupt operations. Its smart alarm filtering minimizes false positives and delivers only timely, actionable alerts. With an intuitive interface and cloud connectivity, DS-Insight with DS-IN helps industrial teams optimize maintenance schedules, improve system reliability, and minimize unplanned downtime.

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Continuous monitoring of vibration, temperature, and load data.

Data is analyzed locally in real time for early anomaly detection.

Data is sent to the central platform for deeper analysis and long-term tracking.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Operators take targeted, fast action based on precise insights.

Entire flow is tailored through DS modules for each industry

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Data is analyzed locally in real time for early anomaly detection.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Operators take targeted, fast action based on precise insights.

Continuous monitoring of vibration, temperature, and load data.

Data is sent to the central platform for deeper analysis and long-term tracking.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Entire flow is tailored through DS modules for each industry

Key Benefits for

Industrial Operations with Delphisonic

Key Benefits for

Industrial Operations with Delphisonic

Up to 95% failure prevention through continuous monitoring of motors, gearboxes, bearings, and rotating machinery — powered by Edge AI anomaly detection before critical faults occur.

Up to 30% maintenance cost savings by transitioning from reactive to predictive strategies — reducing manual inspections, optimizing maintenance intervals, and extending asset life.

Improved system reliability and operational safety, with early detection of issues such as rotor imbalance, bearing wear, or torsional vibration — minimizing risk during production.

Increased equipment availability and faster response, enabled by real-time fault detection, remote diagnostics, and predictive planning — ensuring smoother, uninterrupted operations.

Discover Delphisonic’s solutions to optimize your maintenance

processes and reduce operational risks and costs.

Why Delphisonic?

Why Delphisonic?

Delphisonic’s Industrial

Expertise

At Delphisonic, we have been delivering predictive maintenance and industrial monitoring solutions since 2012 — with a strong focus on industrial manufacturing systems.

We combine AI-powered analytics with edge-based smart sensors to detect failures early, reduce maintenance costs, and ensure uninterrupted production.

We don’t just monitor machines — we engineer them from within, with deep technical know-how and industry-specific insight.

Let’s solve your industrial challenges together.

Delphisonic’s

Industrial Expertise

At Delphisonic, we have been delivering predictive maintenance and industrial monitoring solutions since 2012 — with a strong focus on industrial manufacturing systems.

We combine AI-powered analytics with edge-based smart sensors to detect failures early, reduce maintenance costs, and ensure uninterrupted production.

We don’t just monitor machines — we engineer them from within, with deep technical know-how and industry-specific insight.

Let’s solve your industrial

challenges together.

Guide the future

Request a Demo

Solutions

Trust Center

Solutions

Trust Center

Solutions

Trust Center

© Copyright 2025, All Rights Reserved by Delphisonic