Problems

Oil & Gas Infrastructure

Maintenance Challenges

Equipment in oil and gas operations — such as compressors, pumps, turbines, and pipelines — operate under high pressure, temperature, and continuous mechanical load. Unplanned failures in these systems not only result in costly downtime and repairs, but also pose environmental risks, shorten asset lifespan, and significantly compromise operational reliability.

Problems

Oil & Gas Infrastructure

Maintenance Challenges

Equipment in oil and gas operations — such as compressors, pumps, turbines, and pipelines — operate under high pressure, temperature, and continuous mechanical load. Unplanned failures in these systems not only result in costly downtime and repairs, but also pose environmental risks, shorten asset lifespan, and significantly compromise operational reliability.

Common Oil & Gas System

Failures and Root Causes

Such failures in oil and gas systems reduce operational reliability, increase

maintenance costs, and pose critical risks to facility safety and equipment integrity.

Bearing System Failures

• Inner/outer race wear

• Ball or roller damage

• Cocked bearings

• Axial/radial clearance loss

• Lubrication degradation or absence

Corrosion & Erosion Damage

• Internal pipe wall thinning

• Cracking due to chemical corrosion

• Saltwater-induced surface rusting

• High-velocity flow erosion

• Abrasive wear from solid particles

Compressor & Pump Issues

• Turbine or impeller blade failure

• Shaft bending or torsional stress

• Rotor-stator rubbing

• Flow blockage and pressure surges

• Impeller imbalance and excessive vibration

Common Oil & Gas System

Failures and Root Causes

Such failures in oil and gas systems reduce operational reliability, increase

maintenance costs, and pose critical risks to facility safety and equipment integrity.

Bearing System Failures

• Inner/outer race wear

• Ball or roller damage

• Cocked bearings

• Axial/radial clearance loss

• Lubrication degradation or absence

Corrosion & Erosion Damage

• Internal pipe wall thinning

• Cracking due to chemical corrosion

• Saltwater-induced surface rusting

• High-velocity flow erosion

• Abrasive wear from solid particles

Compressor & Pump Issues

• Turbine or impeller blade failure

• Shaft bending or torsional stress

• Rotor-stator rubbing

• Flow blockage and pressure surges

• Impeller imbalance and excessive vibration

Seal & Pressure-Related Problems

• Gasket leaks

• Deformed sealing rings

• Efficiency loss due to pressure drop

• Valve deformation under overpressure

• Fluid leakage leading to energy loss

Sensor & Monitoring Anomalies

• Thermocouple malfunction

• Drift in pressure or temperature sensors

• Signal distortion from EMI (electromagnetic

interference)

• Loose wiring or poor grounding

• False alarms and missing data

Solutions

DS-GO: Enhancing Oil & Gas System Reliability with AI

Minimize Failures. Extend Lifespan. Ensure Safety.

Traditional maintenance in oil and gas operations relies on fixed intervals and reactive interventions — often missing early-stage failures. In an industry where system reliability is critical, AI-powered predictive maintenance is essential. DS-GO integrates DS-Track, an Edge AI-enabled smart sensor, with the DS-Insight platform to monitor pumps, turbines, compressors, and pipeline systems in real time. By analyzing vibration and load data directly at the edge, it identifies early indicators of faults such as bearing wear or rotor imbalance — improving operational safety and reducing unscheduled maintenance.

Solutions

DS-GO: Enhancing Oil & Gas System Reliability with AI

Minimize Failures. Extend Lifespan. Ensure Safety.

Traditional maintenance in oil and gas operations relies on fixed intervals and reactive interventions — often missing early-stage failures. In an industry where system reliability is critical, AI-powered predictive maintenance is essential. DS-GO integrates DS-Track, an Edge AI-enabled smart sensor, with the DS-Insight platform to monitor pumps, turbines, compressors, and pipeline systems in real time. By analyzing vibration and load data directly at the edge, it identifies early indicators of faults such as bearing wear or rotor imbalance — improving operational safety and reducing unscheduled maintenance.

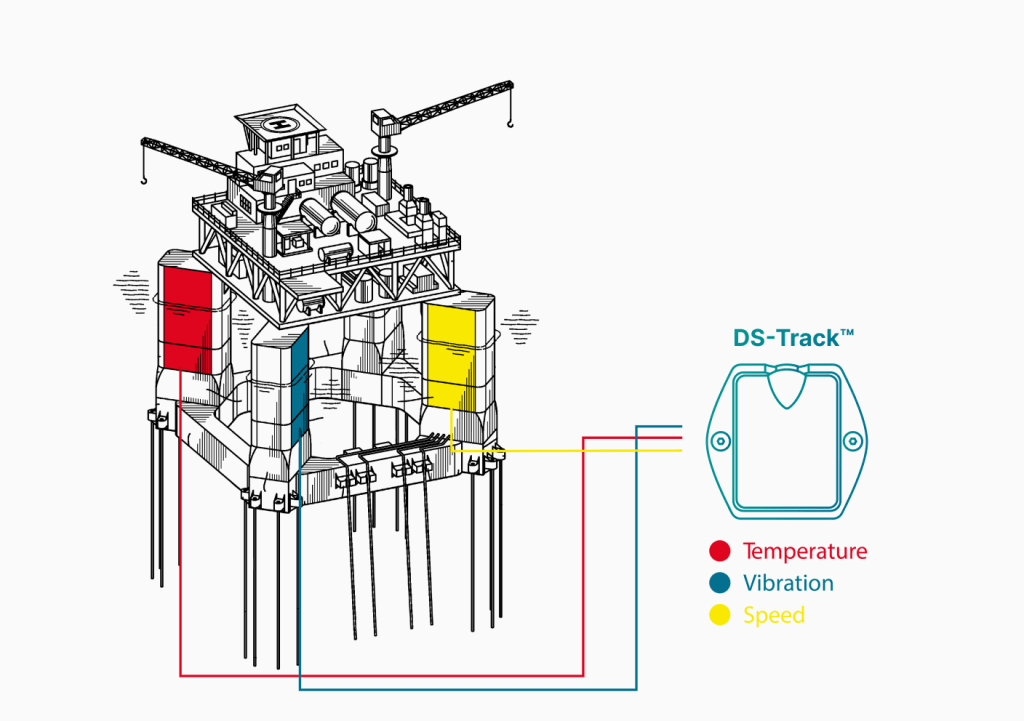

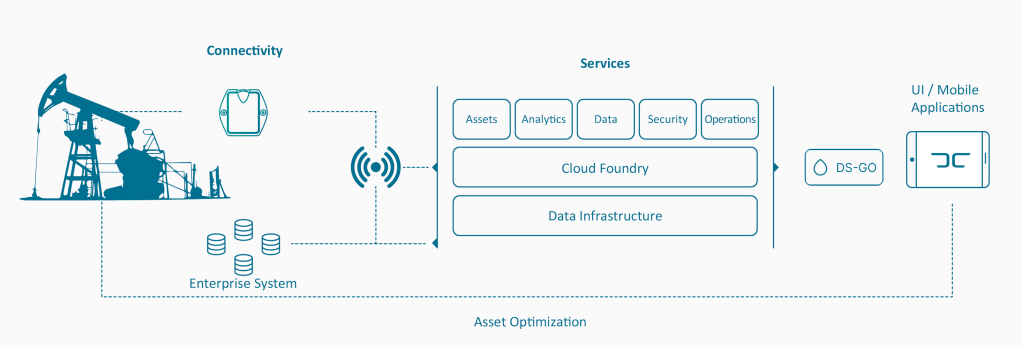

How it Works

Delphisonic’s predictive maintenance system combines Edge AI-powered DS-Track sensors with the DS-Insight analytics platform to continuously monitor oil and gas infrastructure systems in real time.

Data is processed directly on the sensor, enabling early fault detection before critical failures occur.

This helps optimize maintenance planning, reduce unplanned interventions, and enhance operational safety and system reliability.

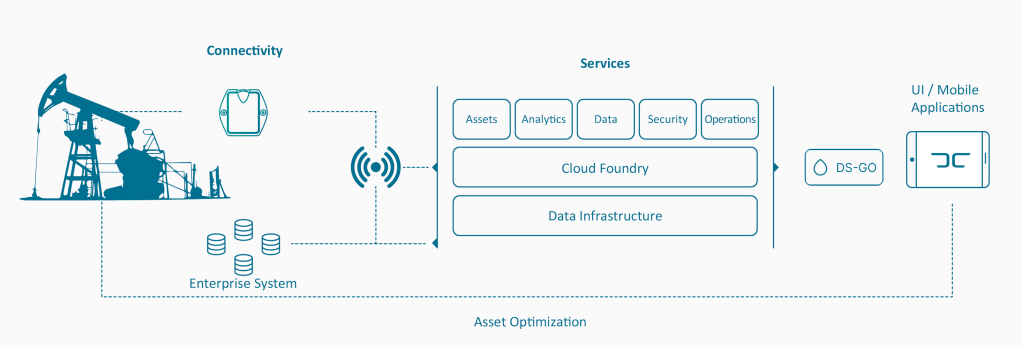

How it Works

Delphisonic’s predictive maintenance system combines Edge AI-powered DS-Track sensors with the DS-Insight analytics platform to continuously monitor oil and gas infrastructure systems in real time.

Data is processed directly on the sensor, enabling early fault detection before critical failures occur.

This helps optimize maintenance planning, reduce unplanned interventions, and enhance operational safety and system reliability.

DS-Track

DS-Track is an Edge AI-powered smart sensor that can be seamlessly integrated into oil and gas infrastructure systems such as turbines, pumps, compressors, and pipeline equipment. It continuously monitors key parameters like vibration, temperature, and dynamic stress, processing the data locally in real time. The data is transmitted—via wired or wireless connections—to the DS-Insight platform, but most anomalies are detected directly on the sensor itself. This enables early warnings and accurate alerts before critical failures occur, ensuring safe and uninterrupted operations.

DS-Track

DS-Track is an Edge AI-powered smart sensor that can be seamlessly integrated into oil and gas infrastructure systems such as turbines, pumps, compressors, and pipeline equipment. It continuously monitors key parameters like vibration, temperature, and dynamic stress, processing the data locally in real time. The data is transmitted—via wired or wireless connections—to the DS-Insight platform, but most anomalies are detected directly on the sensor itself. This enables early warnings and accurate alerts before critical failures occur, ensuring safe and uninterrupted operations.

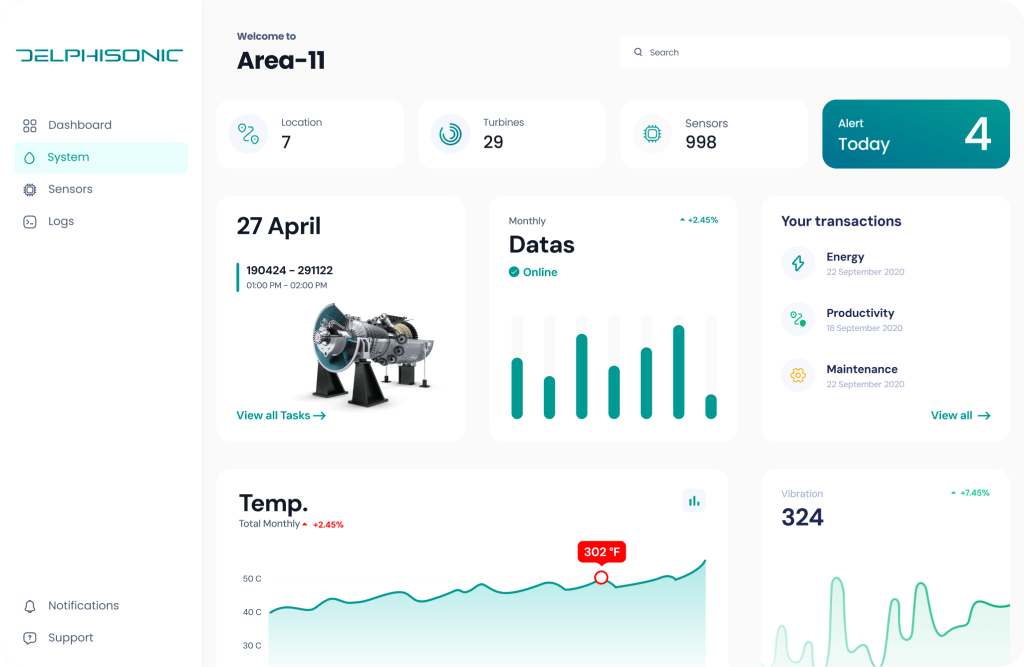

DS-Insight

DS-Insight is Delphisonic’s AI-powered predictive maintenance platform, and the DS-GO module is specifically developed for oil and gas infrastructure systems. It analyzes real-time vibration, temperature, and load data from critical components such as rotors, bearings, gearboxes, pumps, and pipeline equipment — detecting early signs of failure before they compromise operational safety. Smart alarm filtering reduces false positives and delivers only timely, actionable alerts. With its intuitive interface and cloud connectivity, DS-Insight with DS-GO helps optimize maintenance planning, improve system reliability, and minimize costly unplanned downtime.

DS-Insight

DS-Insight is Delphisonic’s AI-powered predictive maintenance platform, and the DS-GO module is specifically developed for oil and gas infrastructure systems. It analyzes real-time vibration, temperature, and load data from critical components such as rotors, bearings, gearboxes, pumps, and pipeline equipment — detecting early signs of failure before they compromise operational safety. Smart alarm filtering reduces false positives and delivers only timely, actionable alerts. With its intuitive interface and cloud connectivity, DS-Insight with DS-GO helps optimize maintenance planning, improve system reliability, and minimize costly unplanned downtime.

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Continuous monitoring of vibration, temperature, and load data.

Data is analyzed locally in real time for early anomaly detection.

Data is sent to the central platform for deeper analysis and long-term tracking.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Operators take targeted, fast action based on precise insights.

Entire flow is tailored through DS modules for each industry

Process

Step-by-Step Summary

DS-Track sensors are mounted on critical assets depending on industry-specific needs.

Data is analyzed locally in real time for early anomaly detection.

Machine learning identifies patterns, detects faults, and recommends maintenance actions.

Operators take targeted, fast action based on precise insights.

Continuous monitoring of vibration, temperature, and load data.

Data is sent to the central platform for deeper analysis and long-term tracking.

Only meaningful alerts are generated—minimizing unnecessary notifications.

Entire flow is tailored through DS modules for each industry

Key Benefits for

Oil & Gas Operations with Delphisonic

Key Benefits for

Oil & Gas Operations with Delphisonic

Up to 95% failure prevention, minimizing downtime through early detection of faults in pumps, turbines, compressors, and pipelines.

Up to 30% maintenance cost savings by shifting from reactive to data-driven strategies, avoiding unnecessary replacements and emergency interventions.

Improved operational safety, with early identification of risks such as bearing wear, rotor imbalance, or seal leakage — reducing environmental and equipment hazards.

Real-time diagnostics and remote monitoring, enabling centralized control and faster response across geographically distributed sites.

Discover Delphisonic’s solutions to optimize your maintenance

processes and reduce operational risks and costs.

Why Delphisonic?

Why Delphisonic?

Delphisonic’s Oil & Gas Expertise

Delphisonic’s Oil

& Gas Expertise

At Delphisonic, we have been delivering predictive maintenance and industrial monitoring solutions since 2012 — with a strong focus on rotating and structural systems in oil & gas operations.

We combine AI-powered analytics with edge-based smart sensors to detect anomalies early, reduce downtime, and ensure the safe and continuous operation of critical infrastructure.

We don’t just observe oil & gas systems — we engineer them from within, with deep technical know-how and field-proven insight.

Let’s solve your infrastructure challenges together.

Let’s solve your infrastructure

challenges together.

Guide the future

Request a Demo

Solutions

Trust Center

Solutions

Trust Center

Solutions

Trust Center

© Copyright 2025, All Rights Reserved by Delphisonic