Railway systems have long been the backbone of national transportation infrastructure. However, as these systems age and expand, maintenance has become increasingly complex and costly. Traditional reactive or scheduled maintenance approaches are proving inadequate in preventing unexpected breakdowns, delays, and accidents. This is where predictive maintenance, powered by artificial intelligence (AI) and smart sensors, is transforming the future of rail operations.

What is Predictive Maintenance?

Predictive maintenance (PdM) is a data-driven strategy that monitors the real-time condition of assets to predict when maintenance should be performed. This approach minimizes unplanned downtime and extends the lifespan of equipment.

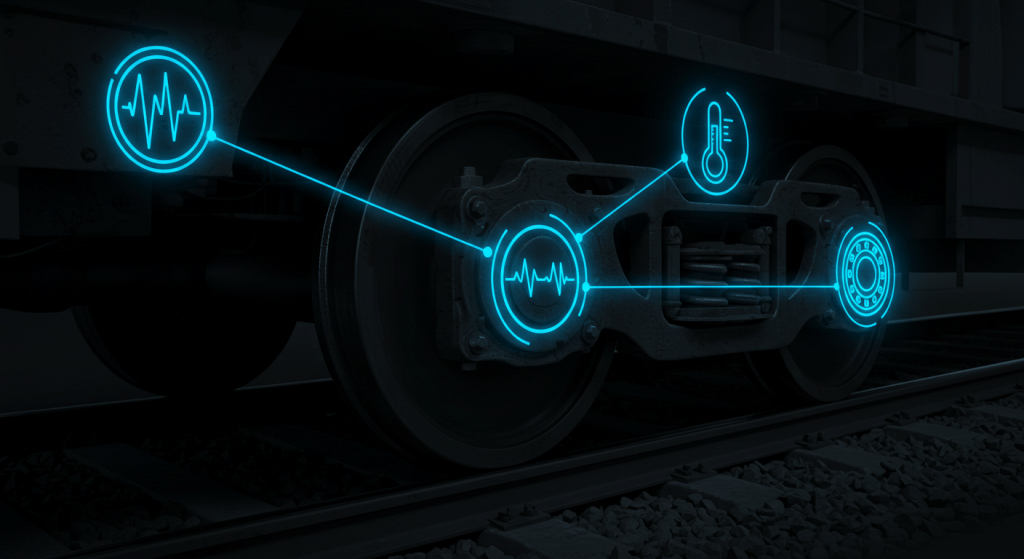

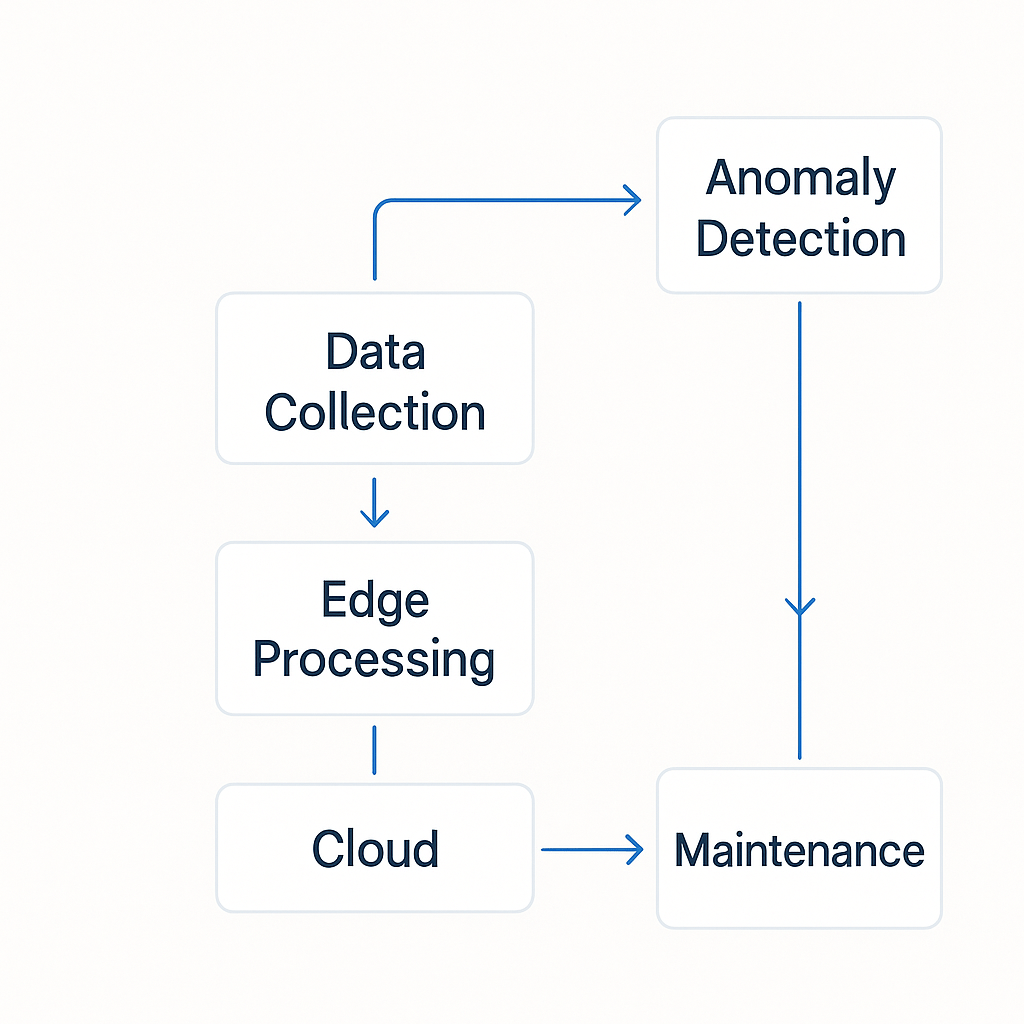

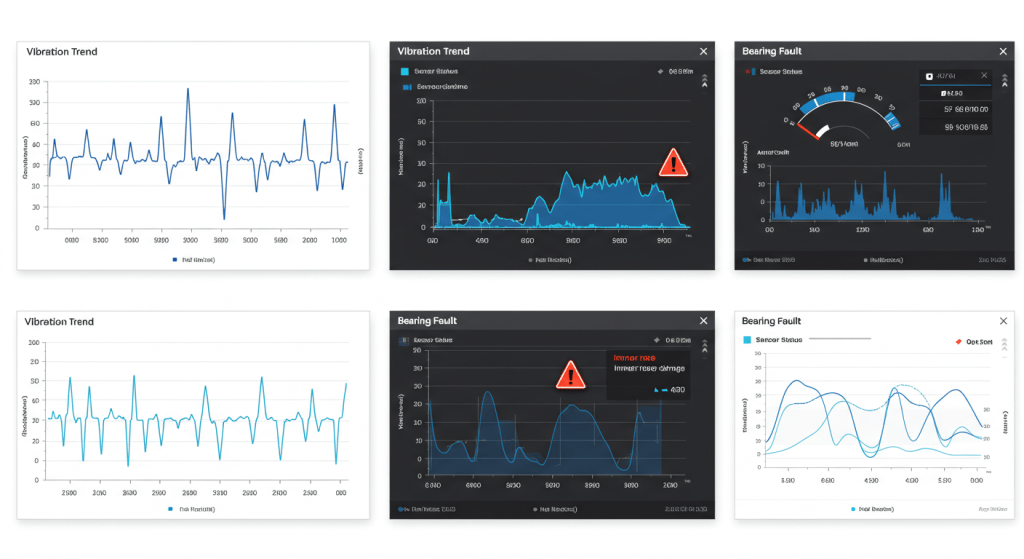

At Delphisonic, our DS-Track AI sensors collect and analyze high-frequency vibration, temperature, and acoustic data directly from bogies, traction motors, and axle boxes. These data points are processed both at the edge and in the cloud using advanced machine learning algorithms that can detect early-stage anomalies before they turn into critical failures.

Why Railways Need AI-Based Solutions Now

The increasing load on metro systems, high-speed trains, and cargo locomotives demands more than routine inspections. Components such as wheelsets, suspension systems, and traction motors operate under extreme mechanical stress and environmental conditions. Even minor defects in bearings or gears can lead to catastrophic failures if not identified in time.

AI-based PdM provides several key advantages:

- Real-time monitoring: Continuous insight into component health without manual intervention.

- Failure prediction: Early detection of wear, misalignment, imbalance, and overheating.

- Reduced costs: Lower maintenance budgets by focusing on actual asset condition.

- Higher safety: Prevent derailments and service interruptions by addressing faults early.

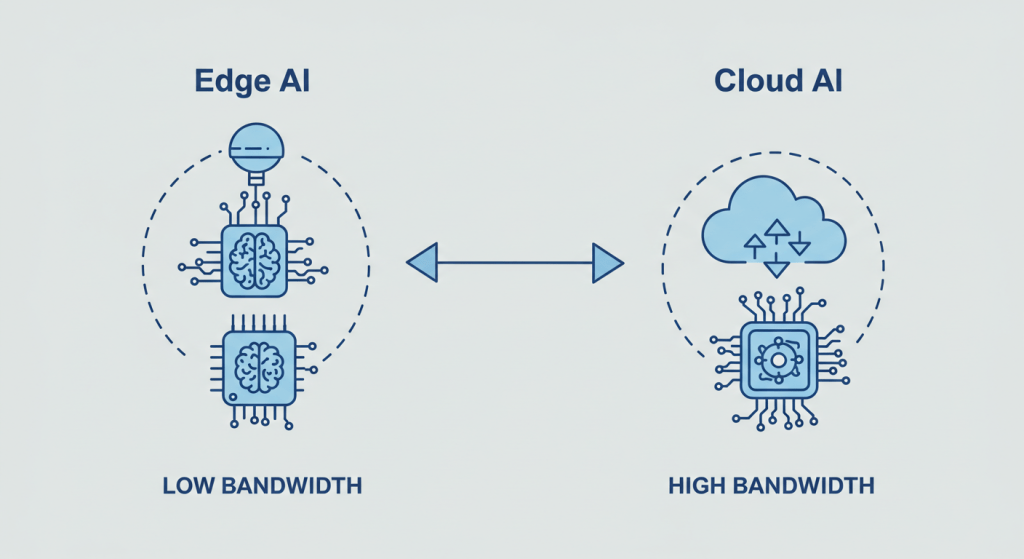

Edge AI: The Key to Real-Time Decision Making

Delphisonic’s embedded AI runs directly on the sensors, reducing the need to send raw data to the cloud. This is crucial for environments with limited connectivity, such as tunnels or remote routes. With edge computing, critical decisions like “hot box detection” or gear mesh faults are made locally within milliseconds.

This architecture:

- Reduces latency

- Saves bandwidth

- Ensures uninterrupted fault detection

- Protects sensitive data locally

Sensor Technology: From Vibration to Insight

Our DS-Track series sensors measure vibration in a wide range—from ±1gE to ±1000gE—with high sampling rates up to 50kHz. With analog MEMS technology (ADXL1002 / ADXL1004), we enable early-stage detection of faults like:

- Bearing inner/outer race damage

- Wheel flats

- Gear tooth wear

- Motor unbalance

- Resonance or misalignment

These physical insights are visualized through our custom dashboards, allowing maintenance teams to plan corrective actions long before a failure occurs.

Real-World Applications: Rail Operators Using Delphisonic

Several national and metropolitan rail operators across Europe and Asia are currently piloting or deploying our technology. For example, Metro Istanbul has integrated DS-Track for condition monitoring of their M5 line bogies. In Kazakhstan, we are working with ALSTOM to monitor freight locomotives in harsh environments where temperature swings from -40°C to +50°C are common.

Future Outlook: Beyond Railways

While rail is our core market, the same technology is being adapted for:

- Wind turbines

- Industrial motors and gearboxes

- Marine propulsion systems

- Oil platforms

- Data center cooling pumps

Predictive maintenance is not just a trend—it is the next standard for industrial reliability and safety.

Conclusion

AI-powered sensors are enabling a new era in railway maintenance. With real-time analytics, edge processing, and advanced diagnostics, railway operators can move from reactive to predictive strategies—saving time, money, and lives.

Delphisonic is at the forefront of this transformation. Want to see our technology in action? Contact us for a demo or explore our solution portfolio at www.delphisonic.com.